« What does Diamond-like Carbon mean? »

Eternal youth for the luxury watch: DLC coatings promise increased resistance and a smooth, pleasant surface in the long term. But how does the coating actually work? Today we explain the basics of the method, how it relates to the PVD process, and what advantages or disadvantages it brings. We’ll also show popular luxury watches in various price ranges that benefit significantly from carbon coating.

PVD process: Basis for DLC coating

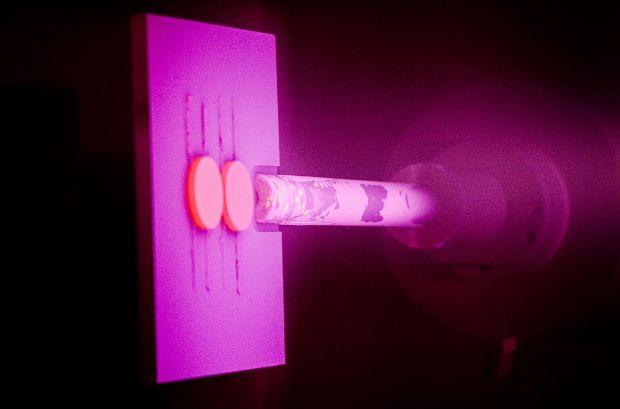

The abbreviations DLC and PVD are widely used in the watch world. Incorrectly, they are often used synonymously, although the meanings are different. PVD stands for “Physical Vapor Deposition” and refers to a process in the course of which a vapor is formed from tiny metal particles. Common materials used are titanium nitride (TIN) and zirconium nitride (ZrN). To prevent the atomized metals from reacting with air, the entire process takes place in a vacuum chamber. The internal temperature of the chamber is kept at moderate levels between 100 °C and 360 °C because, in addition to the metal vapor, the watch case to be coated is also in the vacuum chamber and should not be deformed. The core of the PVD process is simple: The vaporized metals are deposited on the surface of the watch case and form a protective film around 5 micrometers thick. In this process, unlike electroplating, another method of increasing robustness, no chemical reactions take place.

The DLC coating, on the other hand, stands for “Diamond-like Carbon” and refers to one of the possible materials (as an alternative to titanium nitride and zirconium nitride) with which the PVD process can be carried out. In plain language, this means: no DLC without PVD. In German, the material would be called “diamond-like carbon” or “carbon with diamond properties”, which aptly describes the character of the coating.

Black appearance, high robustness: The special features of Diamond-like Carbon

Because if a watch is DLC-treated, its degree of hardness – measured on the Vickers scale – increases considerably. To put this in perspective: a diamond reaches 10,060 Vickers, while plaster, which can be scratched with a fingernail, comes to 36 Vickers. The difference between regular stainless steel and the treated version is interesting: While the naked alloy reaches only 200 to 600 Vickers, depending on the material mixture, the DLC-coated value rises to up to 3,000 Vickers. This explains why ordinary steel watches show a multitude of small scratches after a few years of use, while coated versions still have their like-new aesthetics. By the way, the application of the protective carbon film is not limited to the watch industry: In aircraft construction, car rims, medical technology and many other fields of application, surfaces are DLC-treated.

Advantages and disadvantages of the method

Diving, sports and other outdoor watches in particular benefit from the increased resistance that comes with carbon coating. Although it is not as hard as diamond, it can increase the strength of the surface many times over and increases the likelihood of enjoying a flawless appearance even after intensive use over long periods. Keyword optics: the typical black aesthetics of coated watches enjoy high popularity, especially among sports watches, because it allows differentiation from the crowd, coupled with a cool, masculine look. However, it is not only men who increasingly appreciate the dark, mysterious aesthetics of the coating, but also female watch lovers. Another selling point lies in the feel: similar to ceramic, the treated surface feels smoother than conventional stainless steel and is particularly gentle on the skin. Compared with electroplating, the significant alternative to the PVD process, Diamond-like Carbon is cheaper to implement and relatively environmentally friendly by avoiding chemical reactions.

A central disadvantage of the process comes into play if a scratch does occur. In this case, no spot repairs are possible, but complete removal of the coating is required. The latter solution is time-consuming, cost-intensive and can cause a reduction in the surface quality of the watch case. Ceramic cases have a clear advantage here. In addition, the adhesion of the DLC coating is limited if other coatings have already been applied in advance. However, if the requirements are met, a watch can be subsequently DLC coated, which, in addition to the desired robustness, above all achieves an individual look. Around 2,000 euros must be budgeted for top coatings. Residue-free removal is much cheaper at around 300 euros.

Celebrity watches with the robust treatment

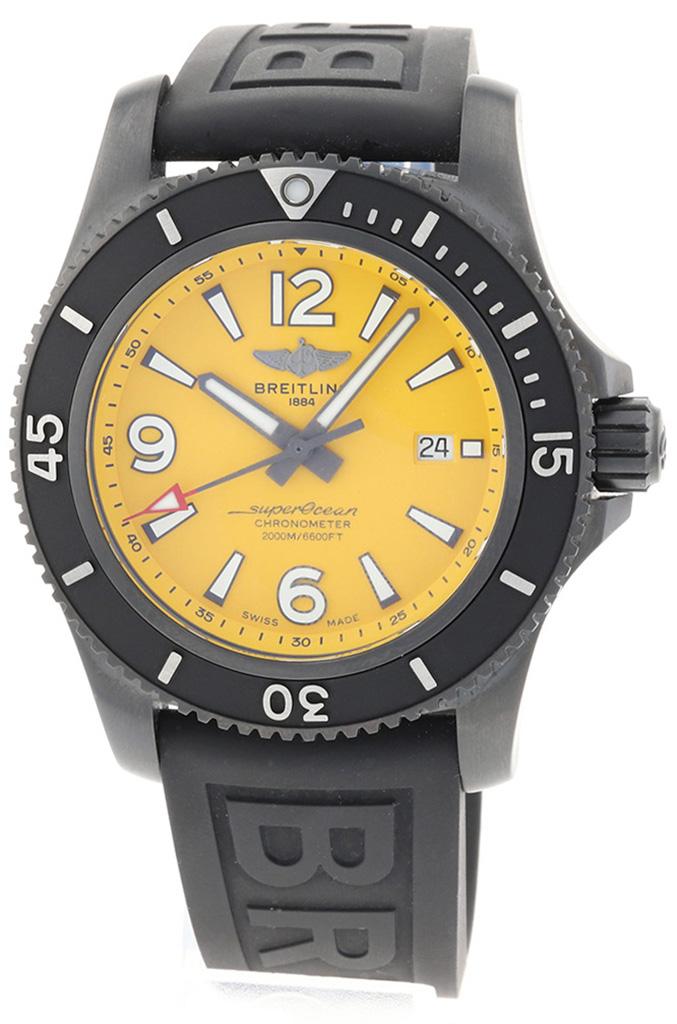

1.) Breitling Superocean Automatic 46 Blacksteel

A monster of the deep sea: what the sperm whale is in the animal kingdom, the Breitling Superocean Automatic 46 Blacksteel is in the watch sector. The combination of diamond-like carbon and 46 millimeters in diameter makes the giant look just as imposing as it actually is, and meets phenomenal water resistance to 2,000 meters, which is exceptional even by Breitling standards. Large Arabic numerals with gorgeous luminous coating underscore the uncompromising focus on functionality. Domed sapphire crystal with anti-reflective coating on both sides, a screw-down crown with two gaskets and a solid stainless steel caseback enable the incredible robustness. Thanks to the non-manufacture caliber 17, the model is also more affordable compared to most other dividers of the luxury brand.

2.) Chopard Mille Miglia GTS Automatic Speed Black

Stylish diving in a dark guise: although the Chopard Mille Miglia GTS Automatic Speed Black is a clear homage to the world’s most famous classic car race over 1,000 miles, the focus is on deep-sea qualities. A whopping 1,000 meters of water resistance is demonstrated by the limited edition of 1,000 pieces, with red accents bringing a fiery note to the dominant black of the 43-millimeter Geneva luxury watch. Strap, dial, case – darkness reigns here. Precision is not neglected either, as demonstrated by the COSC-certified 01.01-M automatic movement with a 60-hour power reserve.

3.) Junghans Meister Pilot

In reference 027/3794.00, the Junghans Meister Pilot offers a powerful sportiness rarely experienced from the otherwise elegant traditional company from the Black Forest. While the aesthetics are characterized by the angular rotating bezel and the noble color gradient of the dial, proven precision prevails inside the 43.3 millimeter stainless steel case, which is water-resistant to 100 meters. In addition to the running time, the automatic caliber J880.4 drives a chronograph function whose limitation to two subdials ensures stylish symmetry.

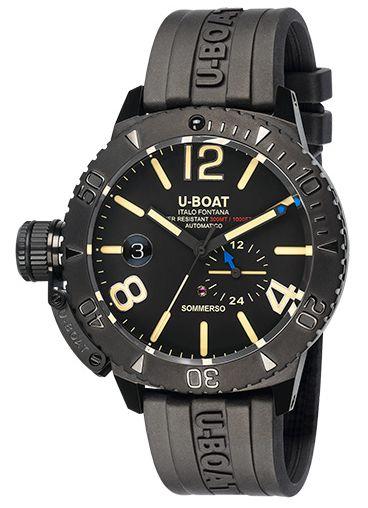

4.) U-Boat Capsoil DLC

If you prefer exoticism, you should get to know the U-Boat Capsoil with the addition in the name “DLC”: designed by probably the most creative watch designer in Italy, Italo Fontana, the luxury watch offers, in addition to a black case, above all an incredibly intense blackness in the dial, which is achieved by filling it with oil. The latter is not complete, but allows an air bubble to float casually over the huge numerals of the extravagant model when worn. No question about it: here the DLC coating becomes a minor matter.

Uhrinstinkt Magazine

Uhrinstinkt Magazine