« From ETA to manufactory »

One of the greatest mysteries of the mechanical watch world is how to construct a precise escapement. Only a few companies possess the expertise to manufacture the extremely delicate assembly that sets the pace. In 2014, Nomos Glashütte succeeded in doing the seemingly impossible: After seven years of development and an investment of eleven million euros, the successful Saxon brand launches its own escapement, the Swing System, and gains complete independence in movement production.

What makes the escapement so complicated?

The escapement, also called assortment or regulator, is both the heart and the most complicated component of a mechanical movement. Acoustically characterized by the typical ticking sound, the escapement gives its timepiece its beat and consists of several components, all of which must have only minimal manufacturing tolerances. Otherwise, the precise display of the time would be impossible.

The main components of the assortment are the balance, hairspring, escape wheel and pallet, supplemented by other microscopic parts. The extremely thin hairspring in particular, which is increasingly made of silicon in modern watch movements for reasons of reliability and robustness, requires an immeasurable amount of effort to produce, which only companies with generous budgets can afford. The central challenge is the small format of the escapement in wristwatches – if the assembly is designed for larger timepieces, the implementation is far simpler.

Knowledge from a past time

The fact that Nomos came up with its own escapement, the Swing System, in 2014 caused quite a stir in the watch world. That’s because the Glashütte company couldn’t use existing literature or mathematical calculations of assortments – the latter didn’t exist. There were historical reasons for this: With the emergence of the first quartz movements in the late 1960s, many people in the watch industry believed that the mechanical movement had no future. They imagined an electronic future on the wrist.

Survival was in the foreground. After the end of the quartz crisis, the decisive knowledge about precise assortments remained with two companies: Swatch subsidiaries ETA and Nivarox. Those who wanted to build mechanical watches from then on had two options: The safe and relatively inexpensive purchase from the Swiss monopolist or the risky in-house development with unknown costs.

90 percent manufacture movement are not enough

It is understandable that, in view of this uncertainty, most watch brands in the mid-price segment opt for the safe route. In practice, however, this means that many of the manufacture calibers we know are not at all one hundred percent in-house developments – although most components are manufactured, assembled and checked “in-house,” the tiny assortment has to be bought in. Nomos Glashütte was in the same position before the Swing System. Since its foundation in 1990, the brand has gradually increased its independence.

First from an aesthetic perspective – with the timeless Bauhaus designs of its original collections Orion, Tangente, Ludwig and Tetra from 1991 – and then from a technical perspective. The most important year for the brand was 2005, when it made its ceremonial step towards manufacture with the presentation of the Alpha movement. The latter enormously enhanced the reputation of the young brand in professional circles and contributed significantly to its recognition as a permanent fixture in the Glashütte watch world. A whopping 80 percent of the work on the movement is now carried out in the hometown.

Swing System from Nomos: The ultimate in-house technology

However, 80 percent is not enough to achieve the goal of complete independence from third-party sources – the Alpha factory’s assortment still has to be sourced from Switzerland. Only the Swing System from Nomos was to change this situation. In 2007, the vision of an in-house escapement was born when the watch manufacturer embarked on the mammoth task in cooperation with the Technical University of Dresden.

The advantage over previous decades: Complex computer simulations allow calculation of the interaction of all components that must mesh smoothly in the assortment. In addition to the structure, the materials are a central challenge in the Swing System. Nomos is receiving support from the Fraunhofer Institute for Material and Beam Technology in Dresden, which is driving the search for modern materials. Key roles on the way to a one hundred percent manufacture caliber are played by the young technicians Theodor Prenzel and Lutz Reichel, who help the Swing System progress from prototype to series production.

“Like landing on the moon”

In 2014, the mega-project is completed after seven years and over 11 million euros in development costs. The Swing System celebrates its glorious world premiere at Baselworld, where the experts cannot help but be amazed. Suddenly, Nomos is no longer one of many brands in the mid-price segment, but belongs to a small circle of elite watch companies that can mass-produce their own regulation system. How significant the step is for the company is aptly expressed by CEO Uwe Ahrendt at the time: it feels like landing on the moon, says the company boss.

Speaking of showcases, the technology made its market debut in the Metro hand-wound watch, followed by its gradual adoption in the rest of the product portfolio. Today, the Swing System is mainly represented in the middle and top of the product world, while most entry-level models are fired by the Alpha.

In which watches does the Swing system work?

To identify watches with the Swing System, you should look for the movement designation “DUW”: Common hand-wound movements with the in-house escapement are the DUW 4101, which is installed in the classic Nomos Glashütte Metro 38 Datum, among others, and the DUW 4401 used in the Tangente Datum Gangreserve.

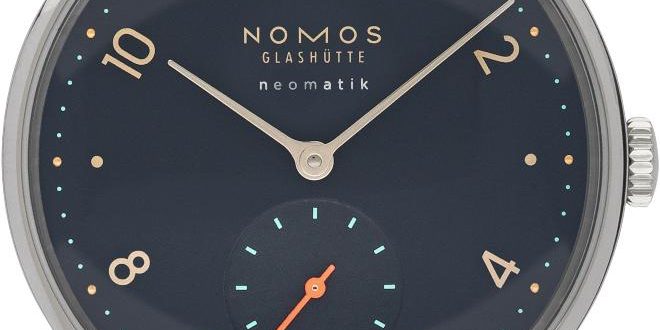

If it has to be an automatic movement, we recommend the Nomos Glashütte Minimatik and the Nomos Glashütte Metro neomatik – both editions are powered by the DUW 3001 and are distinguished by their simple, reduced aesthetics. Enthusiasts can also enjoy the manufacture escapement in automatic watches with the DUW calibers 5201, 5101, 5001 and 6101.

Once the decision has been made in favor of the Swing System, there is of course still the big question of appearance. Those who prefer compact watch sizes should definitely get to know the Minimatik in night blue (Ref. 1205) with its 35.5 millimeter diameter – if automatic winding is preferred, we recommend the 35 millimeter slim Metro neomatik (Ref. 1114).

Uhrinstinkt Magazine

Uhrinstinkt Magazine